Removal of Supports (Negative Support Removal)

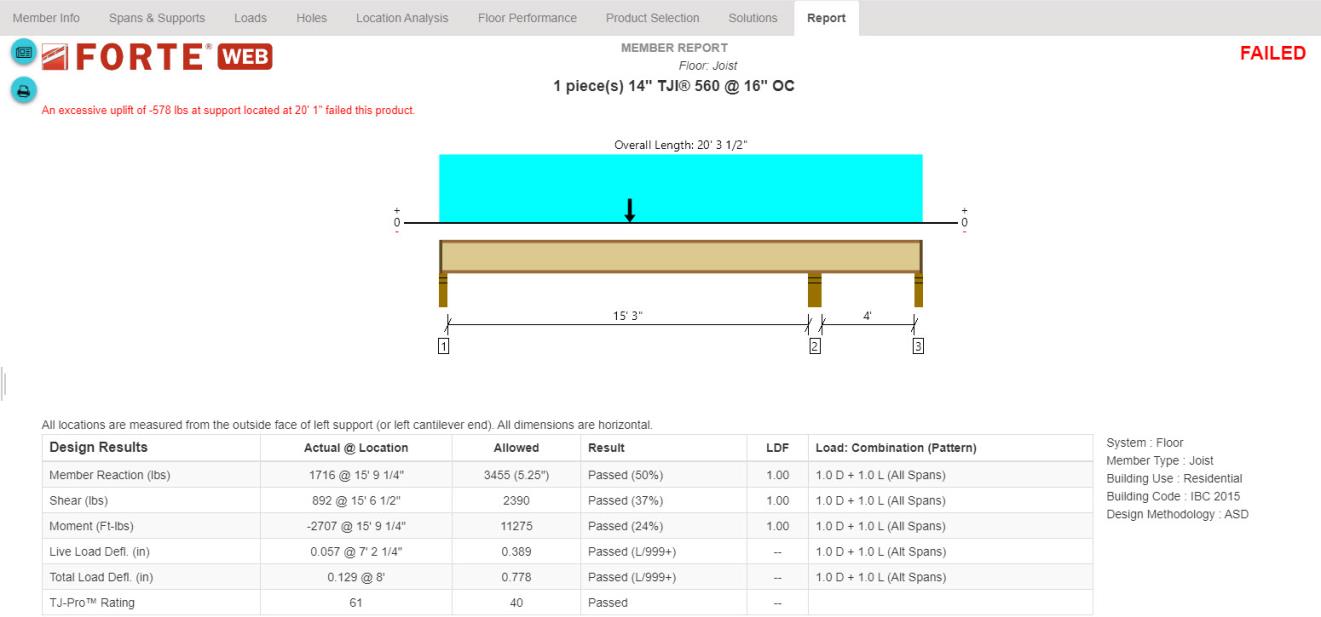

With most single-member sizing software programs, the analysis model assumes that members are “pinned” to all supports – meaning the members are prevented from moving up or down at each support. A design with a long span and a short span has the potential to create exceedingly high uplift reactions at some supports which will fail design as per Support Uplift rules, see below for example. In standard wood frame construction, it can be impractical to restrain these exceedingly high uplift reactions, and often a small amount of upward movement can eliminate them entirely.

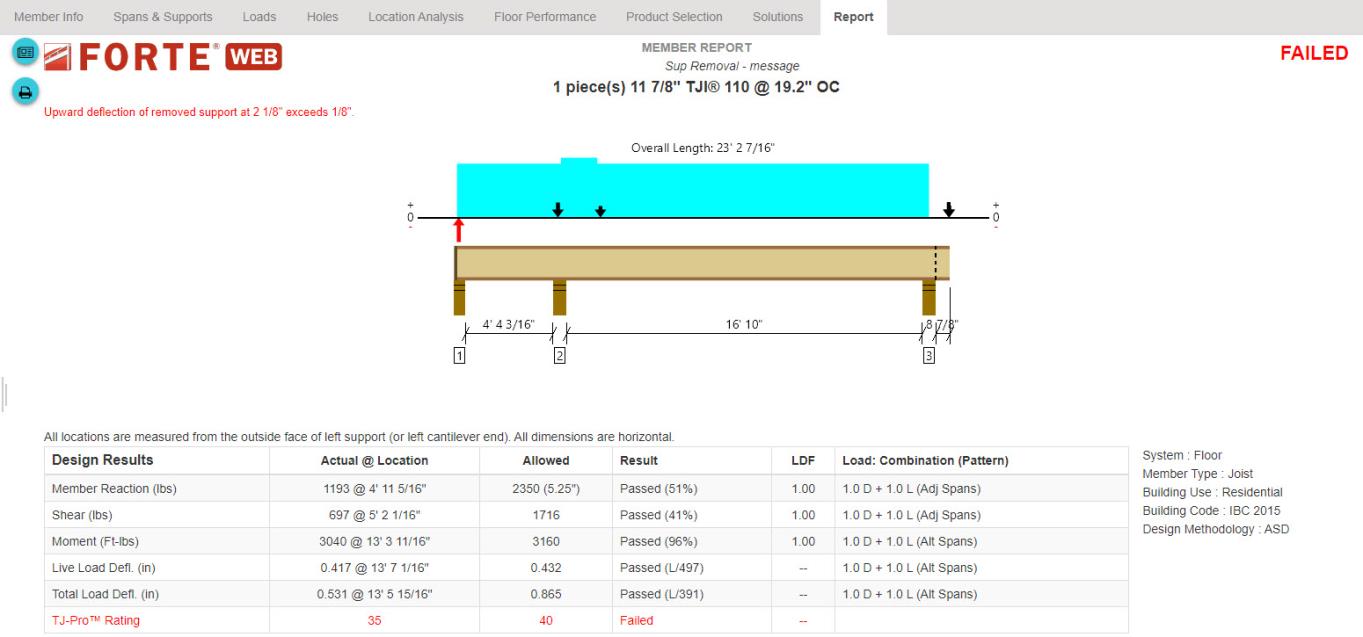

Removal of supports with excessive uplift is the temporary removal of a support during a specific load combination and load pattern analysis. The removal of an end support creates a de facto cantilever and will replace the analysis results previously calculated for when the support was not yet “removed”. This de facto cantilever will be allowed to deflect upwards. The upward deflection will be limited to 1/8” to control how much the member can displace before affecting nearby elements. If the deflection limit is exceeded an error message is reported on the upper left of the results page, see below.

The member setting to allow support removal does not necessarily mean it will always occur. For support removal to occur, the uplift reaction at a specific support must be significant for support removal to occur. If there is not enough uplift, support removal will not occur, and analysis will continue as expected.

The analysis with support removal will create differences in other design parameters, such as moment, shear, reaction, or deflection because we analyze the member as a cantilever during certain scenarios. The loads passed down to the supports will be based on worst case load combinations and load pattern analysis, which will not include the original reaction information before support removal occurred.

Summary

-

When an end support is removed the end span adjacent to that support becomes a de facto cantilever span. Upward deflection will be limited to 1/8” and reported as an error at the top of the report when exceeded.

-

Downward deflections for a cantilever end are not analyzed because there cannot be a downward deflection over a support, even if that support is “released.”

-

Flush end supports are not exempted from being “removed.”

-

Intermediate supports can also be released and will create longer spans.

-

When a support is released software will generate a message “Uplift constraint has been released at support location X inches.”

-

Information from loads to supports will be used to transfer to linked members.